Prosthetic & Orthotic

Associates of Hawaii

1314 S. King Street

Suite 1564

Honolulu, HI 96814

Phone: (808) 597-1773

Fax: (808) 597-1772

Email:

[email protected]

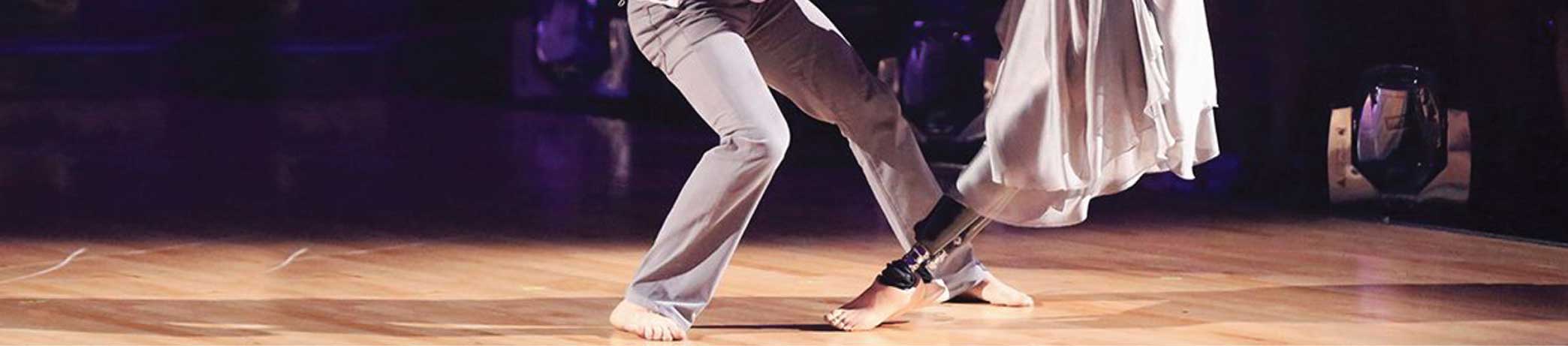

The knee disarticulation prosthetic system was designed taking into account that the amputee is able to bear weight on the end of their residual limb, and long length of the limb increases their control of the prosthesis. Therefore, less support is necessary at the top of the socket, allowing for lower trim lines than a traditional transfemoral socket.

This socket design, named for POA founder Stan Patterson, CP, features a two-piece flexible socket system with an attached carbon fiber strut. This innovative new design allows the patient to utilize their muscles in a way not possible when wearing a traditional prosthetic socket, resulting in a much more natural stride. The carbon fiber strut helps propel the prosthesis, and the patient is able to control it by firing their muscles, giving them a better awareness of the position and movement of their limb.

The components: The patient is first fit with either a silicone liner or prosthetic socks, according to preference and comfort. Once limb has been placed in the socket, an attached suspension sleeve is rolled up, and air evacuated with a vacuum pump.

The patient measured for and fit with a prosthetic liner made of medical grade silicone. These liners are fabricated on-site in our liner manufacturing lab.

The second component of the system is the prosthetic sock. These socks are layered on top of the liner and act as a wick between the liner and the socket and to accommodate for volume changes within the residual limb.

The residual limb is then placed in the socket and air is evacuated through a one-way expulsion valve. Lastly, a sealing sleeve is rolled up to seal against the liner above the socket trim lines.

Prosthetic & Orthotic

Associates of Hawaii

1314 S. King Street

Suite 1564

Honolulu, HI 96814

Phone: (808) 597-1773

Fax: (808) 597-1772

Email:

[email protected]